The benefits of thermography are:

The benefits of thermography are:

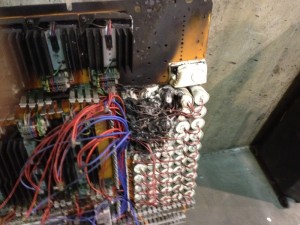

Problems are identified prior to failure. In most cases there is plenty of time to fix the component before it becomes urgent to  fix it. This allows you to plan a convenient time to repair the item and avoid any catastrophic failure during work hours.

fix it. This allows you to plan a convenient time to repair the item and avoid any catastrophic failure during work hours.

Improving safety is another benefit that using thermography will give you.  Workers may be put in a dangerous position due to sudden and unexpected equipment failure.

Workers may be put in a dangerous position due to sudden and unexpected equipment failure.

Reduced outage costs.

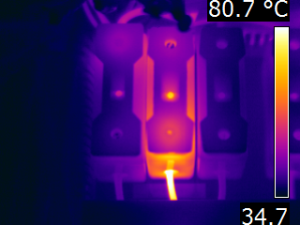

Reduced risk of expensive  damage to plant and property, including damage due to fire.

damage to plant and property, including damage due to fire.

Reduced insurance premiums. In some cases, insurance will not be granted until a thermographic survey is conducted.

Prevents energy wastage caused by resistance in the faults we identify, reducing the cost of energy.

Extension of Asset life leads to reduced replacement costs. For example, thermography can show early identification of worn bearings in a motor. The subsequent repair can prolong the life of the motor and reduce replacement costs.

Lower repair costs as Thermography will pinpoint where the problem is, meaning you are not wasting time repairing what does not need fixing.