Thermal Imaging, Infrared , Hot Spot or Thermographic Surveying provides a picture or image of heat.

Thermographic scanning of electrical switch boards gives us the ability to monitor the thermal condition of equipment like switches, fuses, contactors, transformers, power lines and furnaces. With this thermal information we can determine normal or baseline temperatures.

This is done to reveal thermal anomalies or variances which deviate from the norm. These variances could be due to excessive heat or lack of heat. The anomalies that thermography identifies are used to make a decision on whether to repair now or track the variance over time and plan for repair at a later date.

Deteriorating components, such as poor contact caused by oxidization or loose connection, usually cause excessive resistance. This resistance in turn causes excessive heat. Whilst the human eye cannot detect this heat, thermographic devices can. This is the main benefit of Thermographic Services. It uncovers deteriorating components prior to catastrophic failure allowing you to repair components in planned downtime.

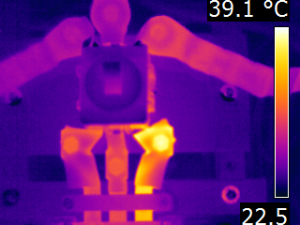

Thermographic surveys are conducted with thermographic equipment. These devices capture information about the heat of the item they are focused on by using thermal detectors. Information from the detectors can be delivered into a monitor or onto a report so that you get images like the one pictured here.

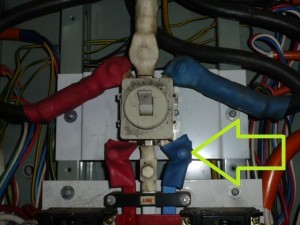

To help identify the location of the fault a standard digital photograph is also included with the thermal image like the one pictured here. Items that are typically surveyed are: switchboards, transformers, motors, machinery, lifts and elevators, refractory, pipe work, cold rooms, boilers, conveyor belts and air conditioning.